Services

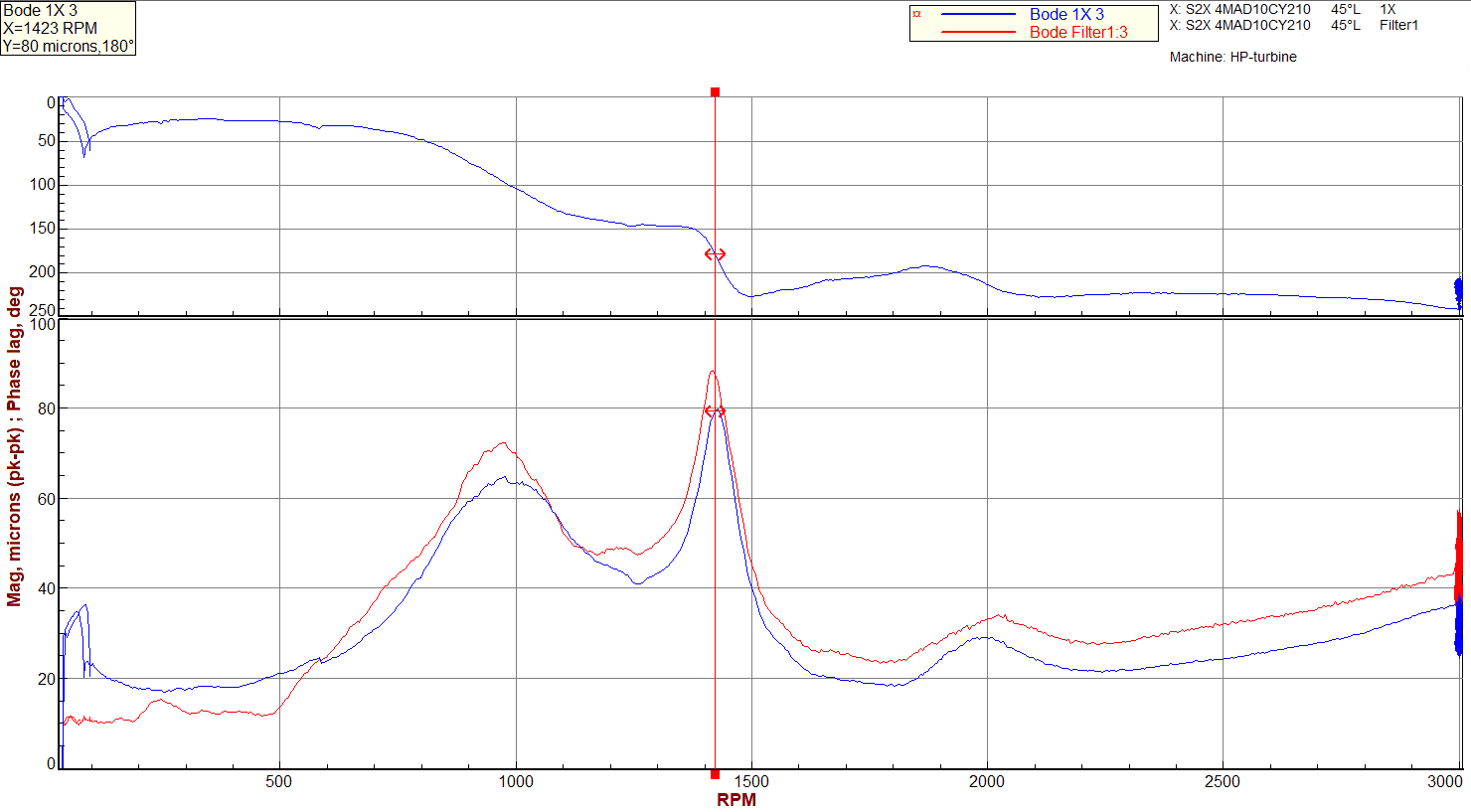

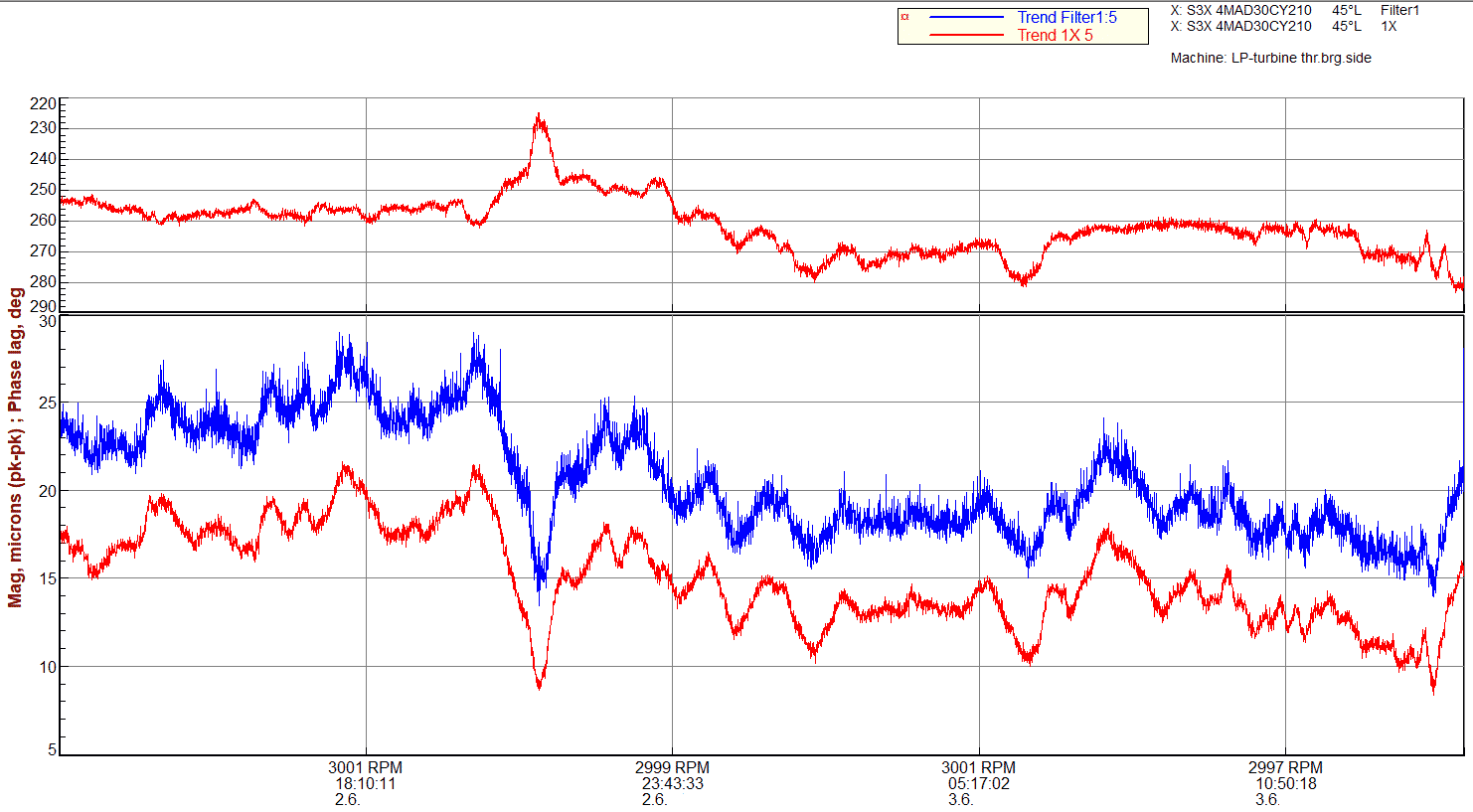

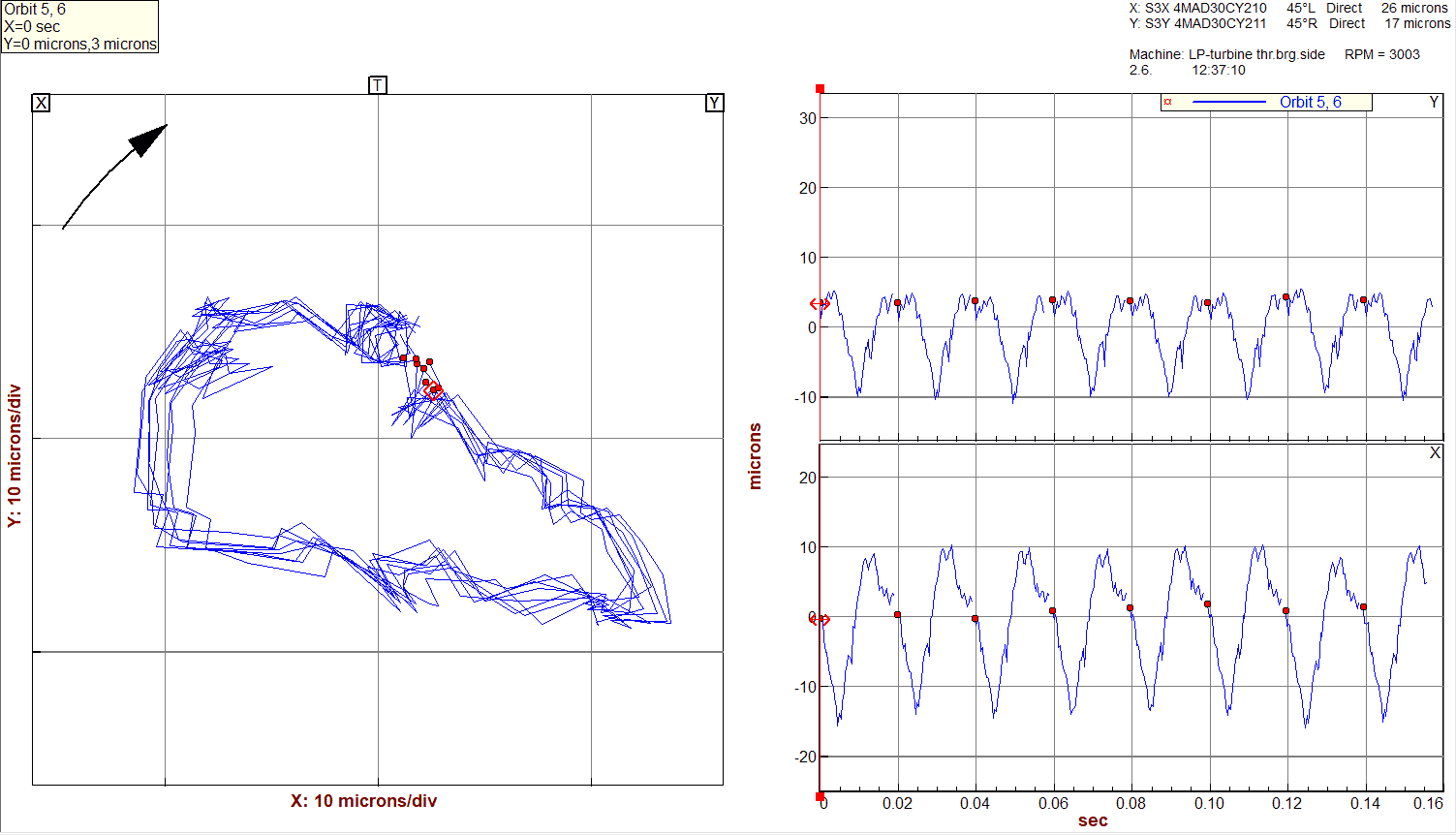

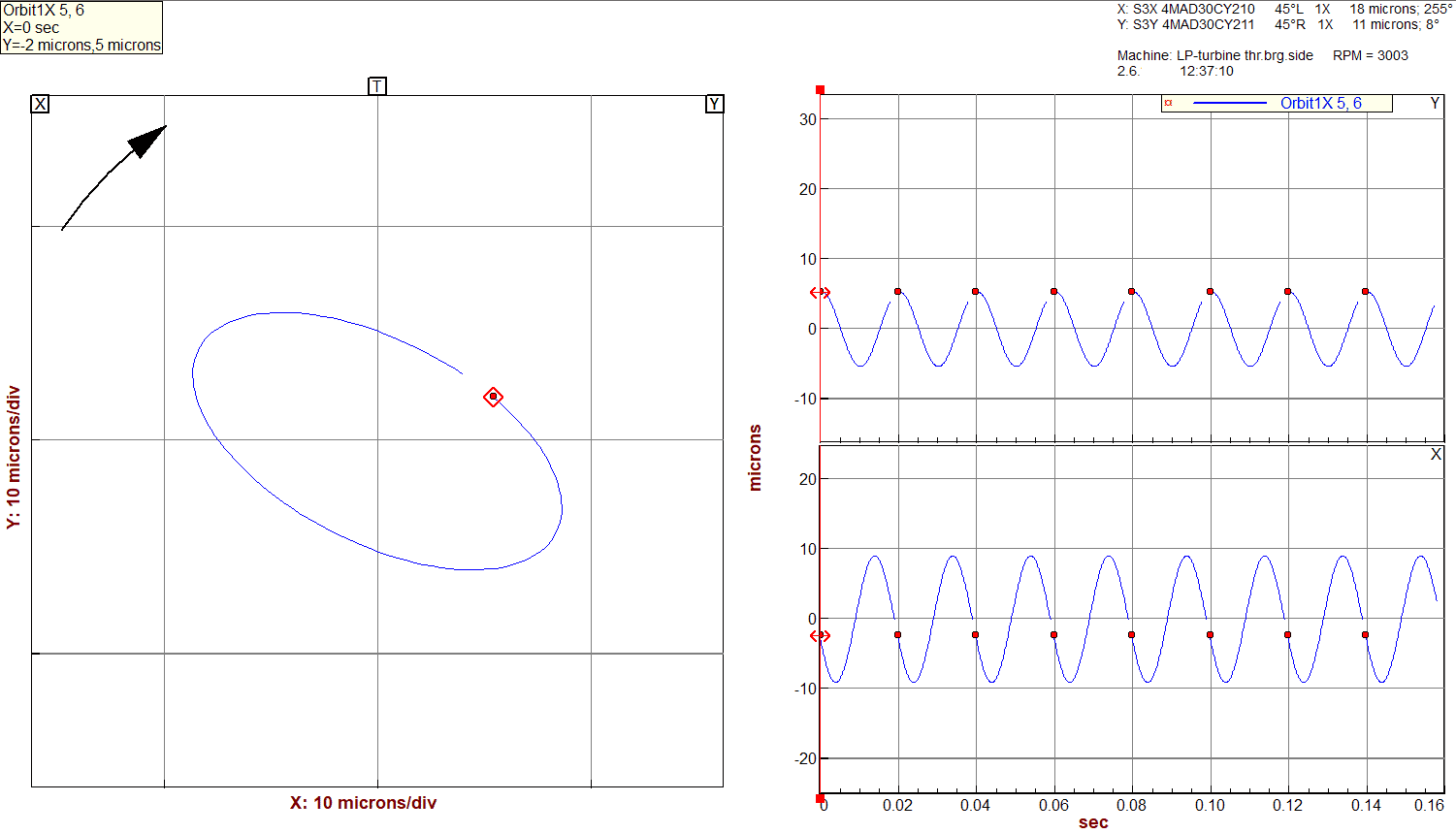

Vibration measurement and analysis services for rotating equipment

Jari Tenhunen

+358 40 158 0993

jari.tenhunen@vibex.fi

Roni Juutinen

+358 40 757 9847

roni.juutinen@vibex.fi

Leave a contact request!

Vibration measurement and analysis services

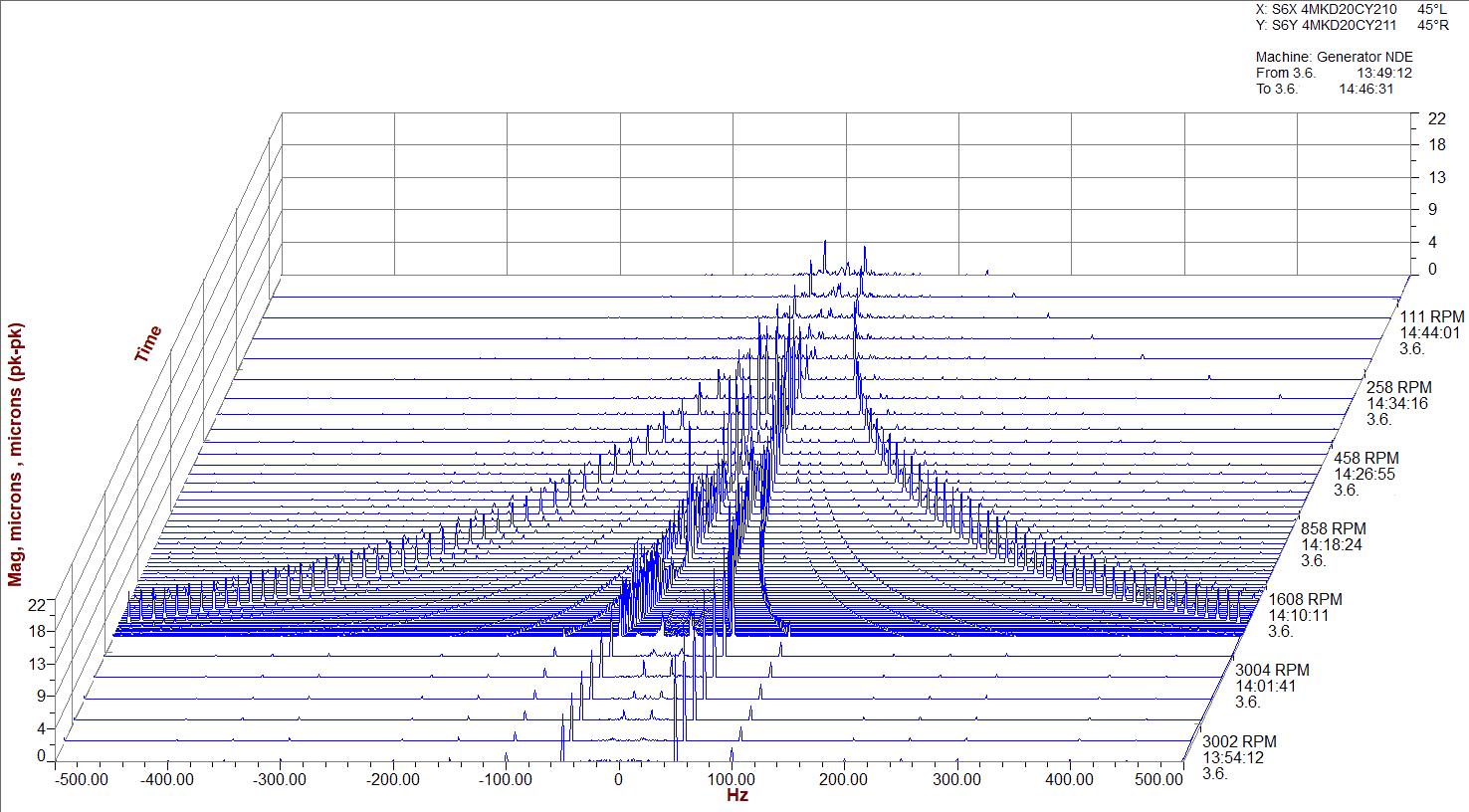

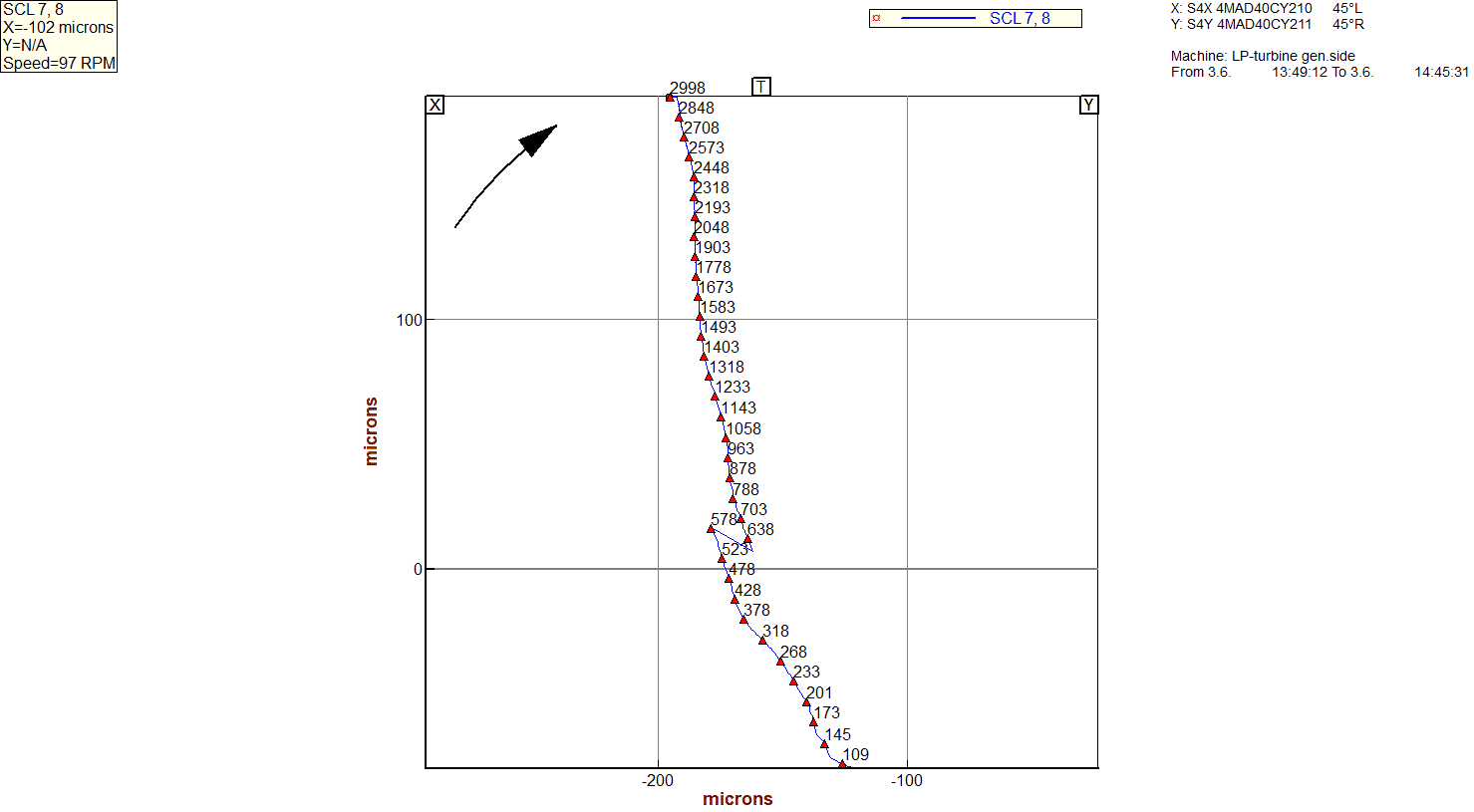

- Specialized in multichannel measurements of large machinery with sleeve bearings such as steam-, gas-, and hydro turbines and generators.

- Measurements to smaller process machinery, like electric motors, pumps, fans and gears.

- Quality control during revisions – measurements pre and post overhauls.

- Acceptance testing for new machinery.

- Vibration troubleshooting.

- Third party assessments.

- Balancing.

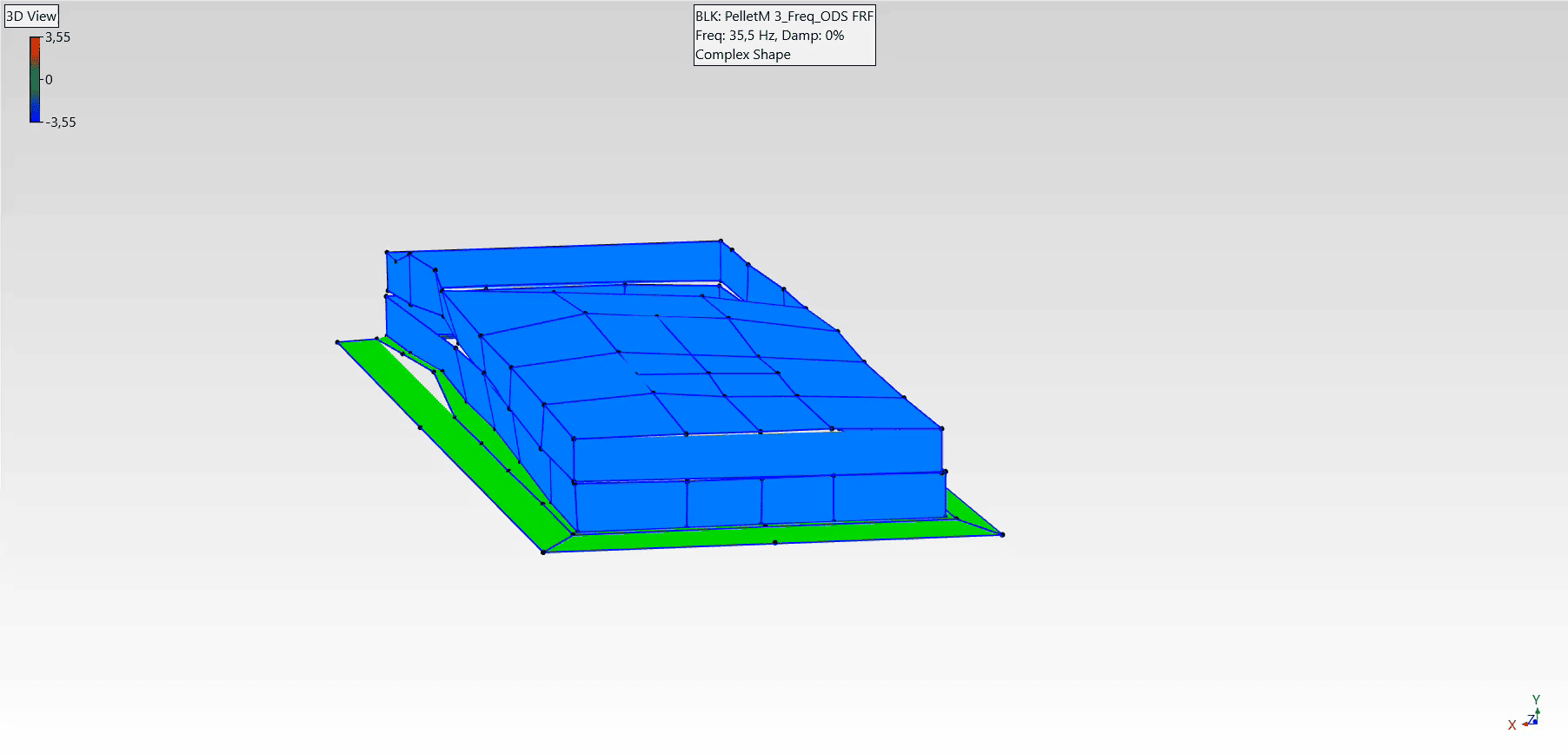

- Operational Deflection Shape (ODS) measurements.

- Modal analysis.

- Consultancy and training of periodical condition monitoring

- Vibrations measurements for static structures such as, piping, valves and boilers.

Operational Deflection Shape (ODS) measurement

- Operational Deflection Shape (ODS) measurement is a troubleshooting method revealing an abnormal deformation pattern of a vibrating structure.

- Abnormality is typically caused by elasticity (=lack of stiffness), damage (= for instance crack, loosen foundation bolt) or installation errors (=for instance loose mounting bolt).

- Measurement is performed during normal, stable operation where the excitation forces are caused by the machine itself.

- Analysis result is presented as an animation. In order to reach necessary demonstrative level, the amplitudes are highly exaggerated and frequency is slowed down in animation.

Experimental Modal Analysis (EMA)

- Experimental Modal Analysis is a testing method for describing and modelling the dynamic behavior of a structure.

- Structure is excited with measured artificial excitation and vibration responses are measured.

- By using measured FRFs (Frequency Response Function) the natural frequencies and associated modal shapes and damping can be defined.

- In addition to troubleshooting this method is used in product development where FEM results are verified with real structures.